現在, 越來越多的人喜歡DIY自己的鋰電池組. 實際上, DIY鋰電池組並不是特別困難, you only need to buy all the necessary accessories, follow the steps below, and you can complete a DIY product by yourself. Below, we take the 18650 battery pack as an example to share with you how to make a lithium battery pack in the factory.

Our example is the lithium battery pack 48V17.5Ah, using Samsung 18650 細胞, the combination method is 13 series and 5 parallel.

The assembly process generally includes the following steps:

No.1 Select the lithium battery cells

Selecting the most closed voltage, 內部阻力, and capacity of 18650 cells is also called the allocation group.

In terms of capacity, it can be that the matching has been completed when the material is received. Before assembling the battery pack, it is only necessary to screen the voltage and internal resistance of the battery cells.

The general screening standard is that the voltage difference is within 5mV, and the internal resistance is within 5mV. The difference is within 3mΩ.

Only the cells within the range of this voltage difference and internal resistance difference can be assembled into a set of lithium battery packs so that the consistency of assembled battery packs will be better, and the performance of the battery packs will be better. The equipment used is a cell sorting and assembling machine.

No.2 Combine the cells in series and parallel

The best way to assemble a battery pack is to put a bracket holder for the battery cells so that after assembling the battery pack, there can be brackets between the cells for isolation. With isolation on the top, the battery pack is safer and avoids vibration affecting the safety of the lithium battery pack.

No.3 Spot welding the battery pack

The material used in spot welding is nickel strip, which is divided into pure nickel strip and nickel-plated steel. The price of pure nickel strips will be much more expensive. Comparatively speaking, the price of nickel-plated steel strips is much cheaper, and the disadvantage is of course that the internal resistance is larger, the overcurrent capability is lower, and it is more likely to rust.

For the thickness of the nickel strip, the current requirements of conventional products, the thickness of the nickel strip is generally 0.15mm, so the power of the spot welding machine is more suitable. If the current is relatively small, you can use a 0.1mm thick nickel strip, and if the current is particularly large, you can use a 0.2mm nickel strip. Nickel strips that are too thin or too thick are not recommended.

When spot welding, it is necessary to pay attention to check the effect of spot welding. The power of the spot welding machine should not be too small, which will lead to virtual welding of the cell, or the power of the spot welding machine should not be too large to avoid frying or spot welding of the cell. After spot welding, the 7KG tensile test shall be passed.

No.4 Weld the protective plate to the battery pack

The BMS used is a ternary lithium 13 series 48V lithium battery BMS. The welding of the BMS needs to be based on the specification of the BMS. The wiring definition diagram shows the welding, from B-, B0, B1, to the last section, B13, all need to be welded according to the specification of the BMS.

After soldering the wires of the BMS, it is necessary to use heat shrinkable sleeves to insulate the solder joints to prevent the solder joints from short-circuiting and malfunctioning.

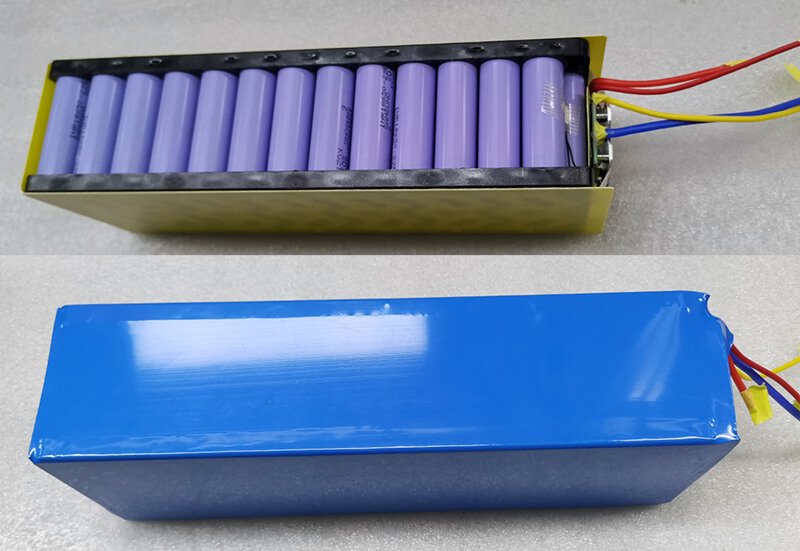

No.5 Insulation packaging shaping battery pack

This step is to carry out insulation packaging and shaping of the battery pack, fix the wires of the battery pack, and pack them.

In order to better insulate the assembly process of the lithium battery pack, the battery pack is blown with PVC film, and glued on both ends behind the PVC film. To prevent water and dust, better protect the lithium battery pack.

No.6 Assemble the battery pack into the battery case

This step needs to connect the exposed wires of the battery pack to the shell material connectors of the casing, including charging and discharging terminals, fuses, switches, ETC.

一般來說, the current of the charging port is relatively small, so the wire diameter used is relatively thin; while the current of the discharge port is relatively large, the wire diameter used is relatively thick, so that the overcurrent will be more ideal.

Soldering the wires needs to be done according to the schematic diagram of the connection between the battery pack and the case.

No.7 Test the lithium battery pack

The final test of the lithium battery pack includes a charge-discharge cycle test, capacity test, internal resistance test, open-circuit voltage test, overcurrent test, overcharge test, over-discharge test, short circuit test, ETC.

In order to verify the performance of the battery pack, the test steps need to be carried out item by item according to the performance requirements of the battery pack. The equipment used includes lithium battery pack charging and discharging aging cabinet, whole product tester, charger, and so on.